The difference between fabric air duct and metal air duct!

There are significant differences in the construction of fabric ducts (also known as cloth ducts or fiber fabric ducts) and traditional metal ducts (such as galvanized iron ducts). The following is a detailed comparison of the two from multiple perspectives:

Conceptual Differences:

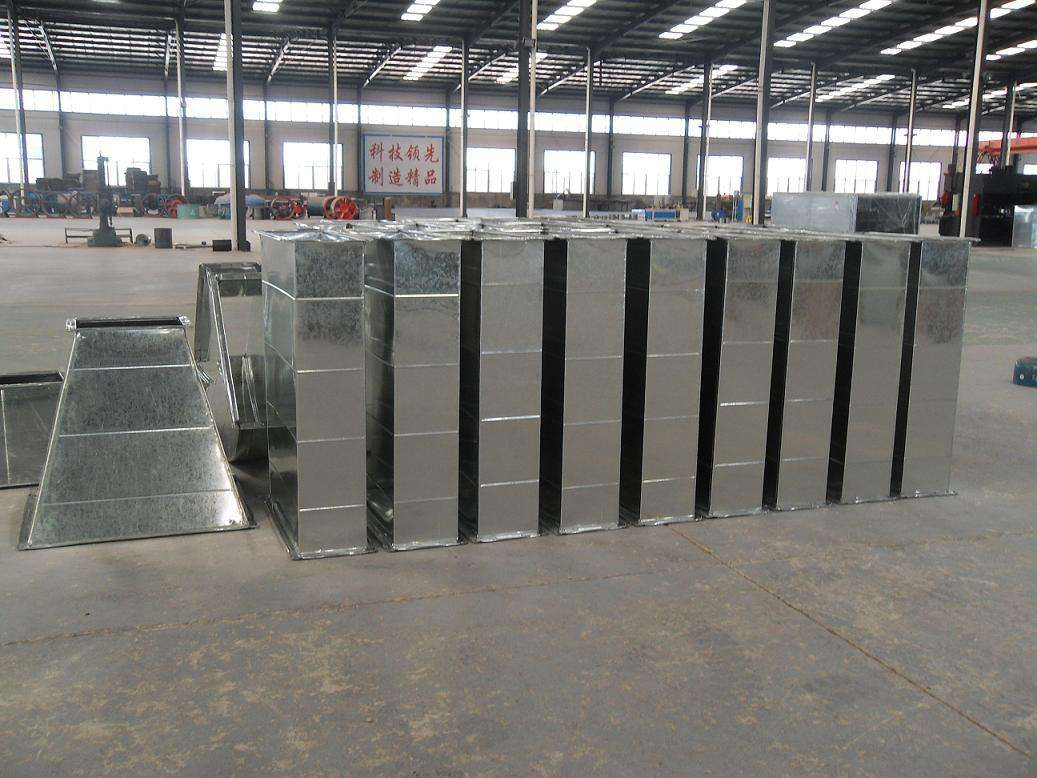

Traditional metal ducts are closed conveying systems whose core mission is to transport air to a designated location without leakage, providing either point-based or surface-based air distribution through outlets (such as louvers and diffusers).

Fabric ducts are themselves a terminal air distribution system. Air is evenly distributed through micropores or slits in the duct wall, achieving surface-based air distribution and more uniform overall air distribution.

Weight Comparison:

Traditional metal ducting: Materials and handling are heavy, including galvanized iron sheets, brackets, flanges, insulation, and mufflers. This requires large equipment (such as forklifts and lifts) and significant manpower.

Fabric ducting: Extremely lightweight, primarily composed of a flexible fiber fabric duct bag, a suspension system (wire ropes and rails), and aluminum alloy fittings. A single person can handle an entire roll of duct, a significant advantage. This significantly reduces the difficulty, cost, and risk of vertical transportation and on-site handling!

Construction and Installation:

Traditional metal ducting: The installation process is complex and involves many steps, including measuring and cutting, joint fabrication, flange installation, duct segment connection, sealant application, insulation installation, numerous supports and hangers, air vent installation, damper installation, and muffler installation, as well as light leakage testing.

Fabric ducting: Simple and requires fewer steps. The installation involves installing the suspension system (wire rope/slide rails), unrolling the duct, inserting it into the suspension system, connecting the air supply plenum, and then straightening and securing the ends. This requires minimal technical skills. Fabric ducting simplifies the process by over 80%. Without the need for joints, flanges, insulation, or sealant application, installation is extremely fast.

Installation Cost:

Traditional metal ducting requires high installation tools and personnel, including specialized sheet metal workers, electricians, and welders. Complex tools include shears, seaming machines, welders, electric drills, rivet guns, and scaffolding.

Fabric ducting can be operated by ordinary workers after brief training. Simple tools include a ladder, tape measure, wrench, and a hand drill (for installing hanging points). Fabric ducting significantly reduces the need for specialized labor and heavy tools, reducing labor costs and the difficulty of scheduling specialized work.

Installation Difficulty:

Traditional metal ducting: Coordination with other work types is challenging. Ducting is bulky and heavy, requiring optimal space above the ceiling. It often competes for space with fire protection piping, cable trays, water pipes, and other components, requiring strict adherence to the BIM integrated piping layout.

Fabric ducting: Coordination is simple. Flexible and lightweight, it can be installed close to the floor, easily bypassing obstacles, and offers exceptional flexibility. Installation can even be delayed until most piping is installed. Fabric ducting, a seamless, seamless solution, is a crucial coordination tool, resolving one of the HVAC industry's biggest pain points and is particularly suitable for complex, compact venues.

Construction Time:

Traditional metal ducting: The construction period is long, from fabrication to installation, and is a critical factor affecting project schedules.

Fabric ducting: The construction time is extremely short, typically 1/3 to 1/5 of that of traditional ducting. Large venues can be installed in just a few days. Fabric ducting can significantly shorten project construction timelines, helping owners open or start production faster, and generating significant economic benefits.

Environmental and Safety:

Traditional metal ducting: Site environments and waste disposal are poor. Cutting and welding produce noise, metal shavings, and dust. Insulation fibers are harmful to worker health. Large amounts of industrial waste are generated.

Fabric ducting: Environmentally friendly, with virtually no cutting, noise, or dust. Minimal packaging materials are required, resulting in virtually zero on-site waste. Fabric ducting is more aligned with the principles of green and clean construction.

Maintenance Costs:

Traditional metal ducting is difficult and costly to modify and maintain. Modifications require cutting, welding, and re-insulation, generating significant waste and garbage. Cleaning requires professional disassembly and cleaning, which is very inconvenient.

Fabric ducting is extremely easy to modify. Simply move the hanging hooks to adjust the direction and height. It can be completely disassembled and directly washed in an industrial washing machine, then hung up again after drying. Fabric ducting offers superior adaptability and maintainability throughout its lifecycle, making it particularly suitable for commercial spaces subject to changing business formats.

Applicable Scenario:

Traditional metal ducting: Commonly used in a wide range of applications, applicable to almost all locations, particularly those requiring high cleanliness, pressure resistance, and corrosion resistance, such as hospital operating rooms, electronics factories, and chemical warehouses.

Fabric ducting: Selectively applicable: Preferred for large spaces and high ceilings, such as stadiums, convention centers, airports, large supermarkets, logistics warehouses, industrial plants, and swimming pools.

Ventilation Duct Selection:

Core Advantages of Traditional Metal Ducts: Robust structure, high-pressure and high-temperature resistance, excellent fire and corrosion resistance, mature system, and wide applicability. Disadvantages: Complex construction, long construction time, heavy weight, uneven air distribution that can create dead spots, condensation, and difficulty cleaning.

Core Advantages of Fabric Ducts: Quick construction, uniform and comfortable air distribution, lightweight, aesthetically pleasing, easy to clean, and highly flexible. Disadvantages: Limited pressure resistance, poor resistance to scratches from sharp objects, and unsuitable for environments with extremely high temperatures or corrosive gases.

Fabric ducts revolutionize construction by simplifying and speeding up the installation process, but their application has specific limitations. During the design phase, the most appropriate and efficient air distribution system should be selected based on the building's specific functions, requirements, and budget.

The two are complementary, not substitutes. Fabric ducting excels in its area of strength (large spaces), but metal ducting is irreplaceable in specific applications.